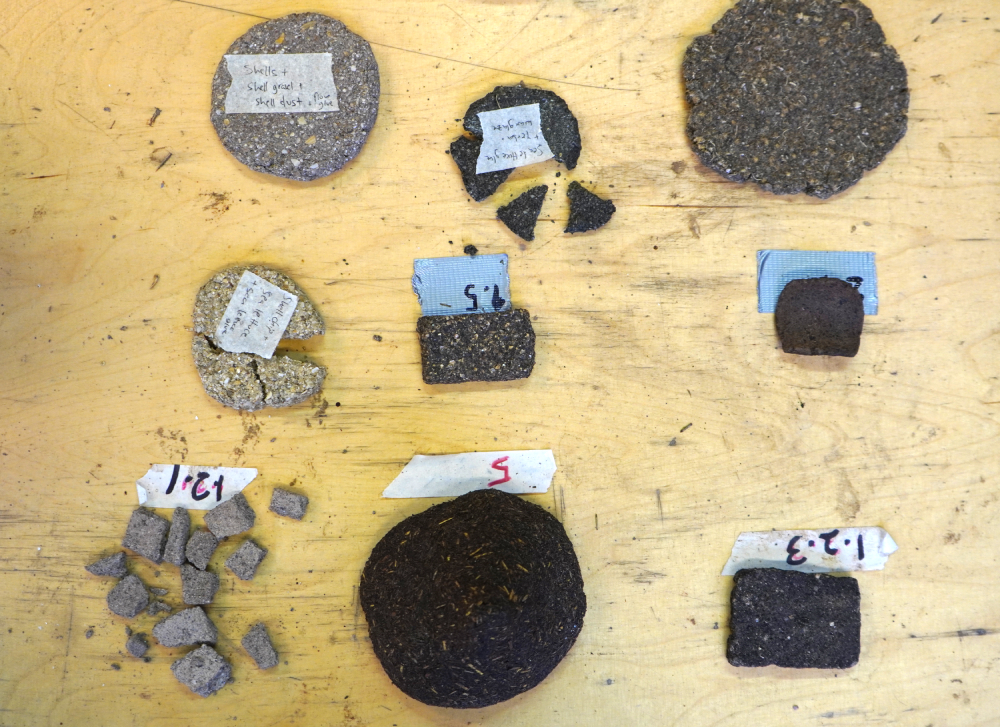

Shell Composite

This material is derived from the shells of Mytilus edulis, commonly known as the blue mussel, which are sourced from local restaurants after culinary use. These establishments typically discard large quantities of mussel shells, which are then collected to create a sustainable composite material.

![]()

Processing:

The collected mussel shells undergo a cleaning process to remove organic residues. Once cleaned, the shells are ground into a fine powder. This shell powder is then mixed with seaweed, which serves as a natural binder. The seaweed enhances the structural properties of the composite and adds a unique textural quality.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

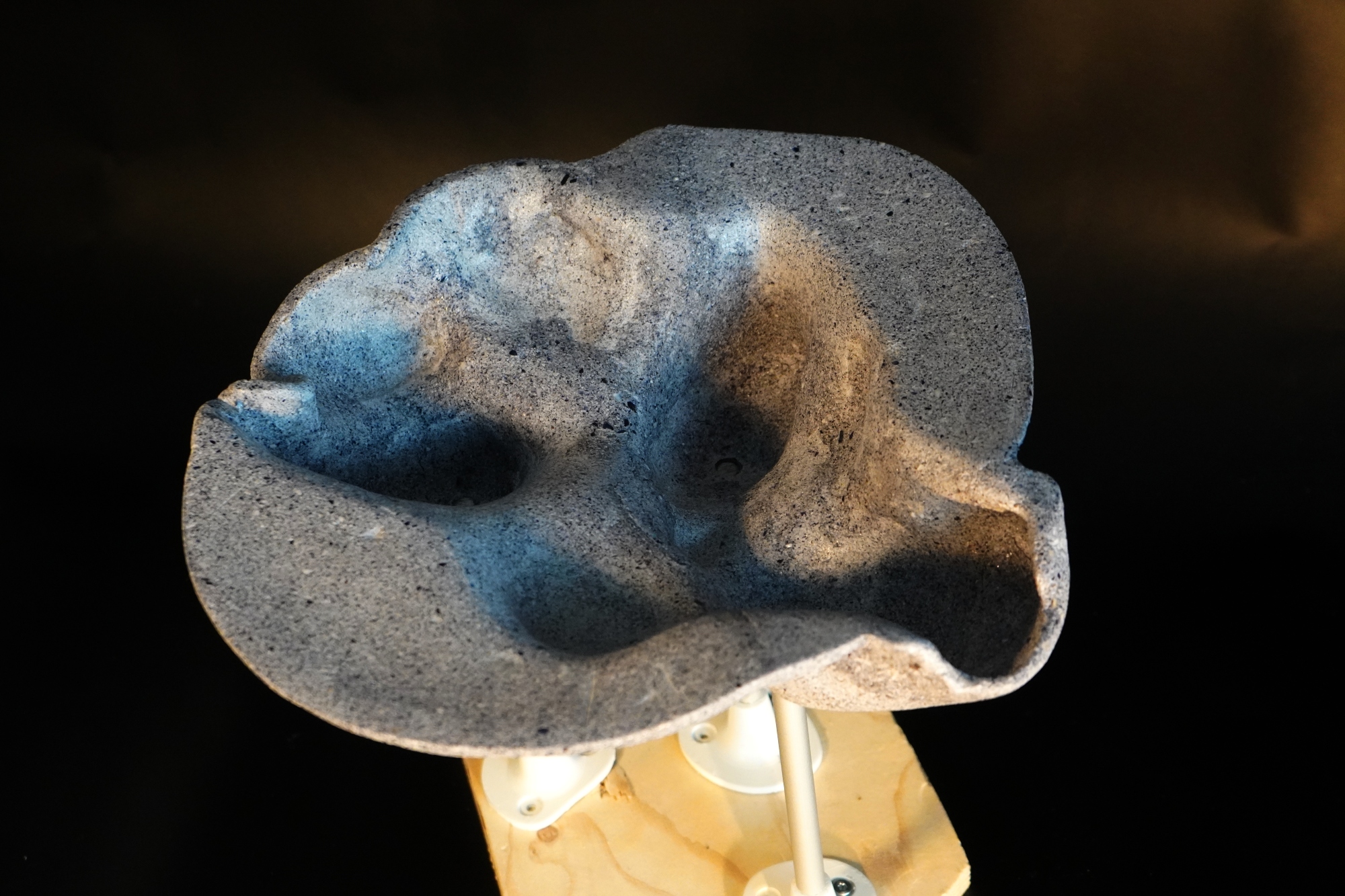

Properties:

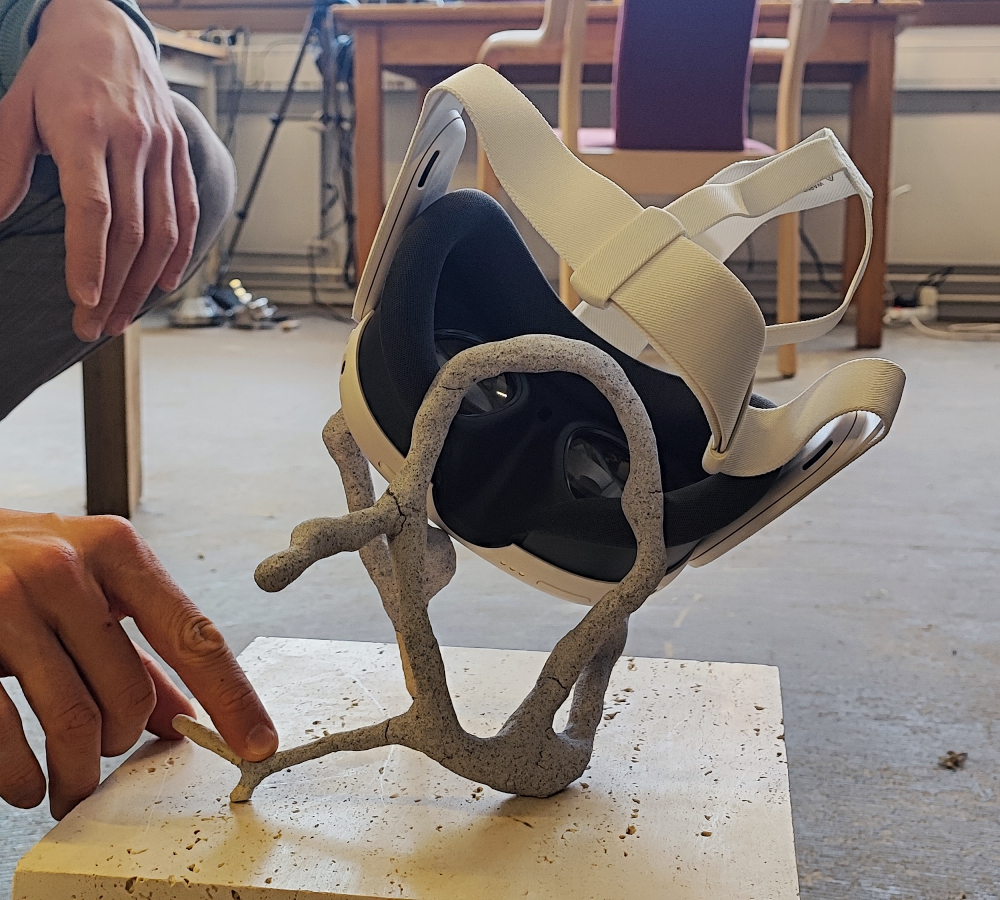

The resulting material exhibits characteristics similar to clay, with good moldability finish. It is primarily composed of calcium carbonate (CaCO3), making it strong and durable yet lightweight. The natural coloration of the shells lends a unique pattern to each batch of material, reflecting the organic origins and sustainable process.

It can be molded into various forms and structures.

![]()

![]()

![]()

![]()

![]()

![]()

Sustainability Highlights:

- Waste Reduction: Utilizes bio-waste from the restaurant industry, reducing landfill contributions.

- Local Sourcing: Employs locally obtained seaweed, minimizing transportation emissions and supporting local ecosystems.

- Biodegradable Components: Composed of natural materials that are biodegradable, contributing to a reduced environmental footprint.

![]()

Circular Economy Integration:

This material exemplifies the principles of the circular economy by transforming discarded mussel shells into a valuable resource for creative industries. It encourages the reuse of bio-based waste and supports sustainable practices in material production, promoting a shift towards more circular and sustainable modes of production and consumption in the art and design sectors.

![]()

This material is derived from the shells of Mytilus edulis, commonly known as the blue mussel, which are sourced from local restaurants after culinary use. These establishments typically discard large quantities of mussel shells, which are then collected to create a sustainable composite material.

Processing:

The collected mussel shells undergo a cleaning process to remove organic residues. Once cleaned, the shells are ground into a fine powder. This shell powder is then mixed with seaweed, which serves as a natural binder. The seaweed enhances the structural properties of the composite and adds a unique textural quality.

Properties:

The resulting material exhibits characteristics similar to clay, with good moldability finish. It is primarily composed of calcium carbonate (CaCO3), making it strong and durable yet lightweight. The natural coloration of the shells lends a unique pattern to each batch of material, reflecting the organic origins and sustainable process.

It can be molded into various forms and structures.

Sustainability Highlights:

- Waste Reduction: Utilizes bio-waste from the restaurant industry, reducing landfill contributions.

- Local Sourcing: Employs locally obtained seaweed, minimizing transportation emissions and supporting local ecosystems.

- Biodegradable Components: Composed of natural materials that are biodegradable, contributing to a reduced environmental footprint.

Circular Economy Integration:

This material exemplifies the principles of the circular economy by transforming discarded mussel shells into a valuable resource for creative industries. It encourages the reuse of bio-based waste and supports sustainable practices in material production, promoting a shift towards more circular and sustainable modes of production and consumption in the art and design sectors.

MUSSEL SHELL

MUSSEL SHELL